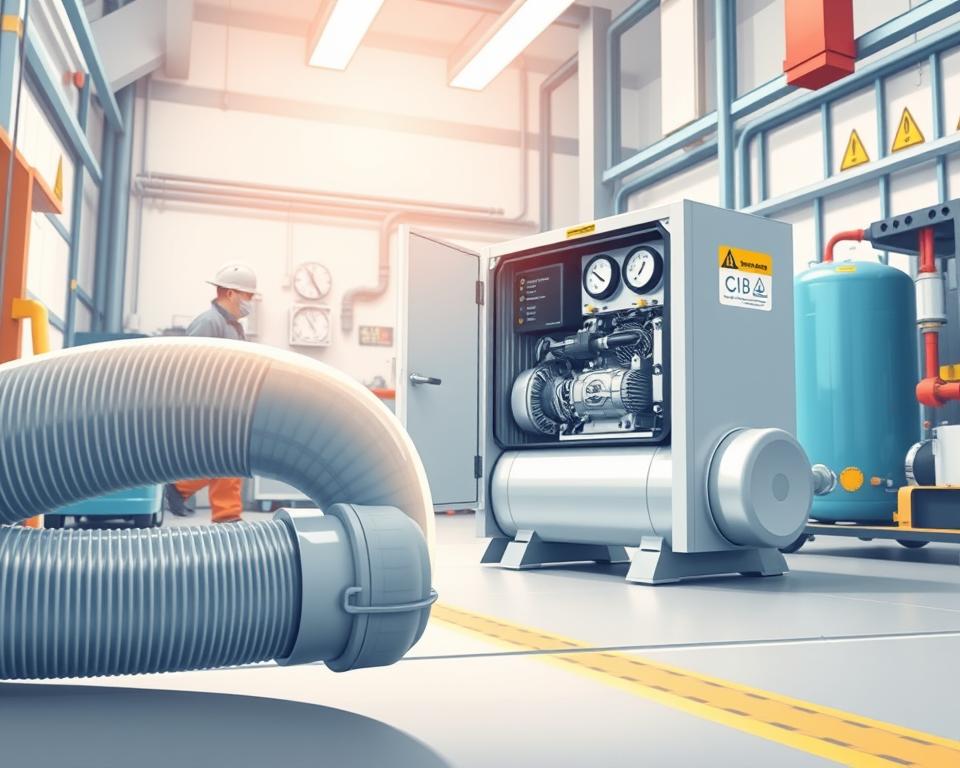

Everything You Need to Know About PVC Air Compressor Piping

You might be surprised to learn that a failure in a compressed air system can unleash power on par with dynamite. Many facilities still use piping systems made from risky materials, unaware of the dangers. Here’s why you must prioritize safety over cost when selecting PVC pipe for air compressor lines.

Although some plastics gain popularity, OSHA flatly forbids their above-ground application. Over time, exposure to oils and temperature changes weakens them, leading to catastrophic failures. Safe-rated pressures can still result in deadly bursts.

For reliable alternatives, Installation Parts Supply offers durable solutions like aluminum. Investing in proper materials avoids costly fines and keeps workplaces secure. Here’s how to assemble a risk-free system.

Primary Conclusions

- OSHA bans certain materials due to explosion risks.

- Temperature changes can halve pressure ratings.

- Material becomes brittle with age, upping rupture chances.

- Switching to aluminum vastly improves safety.

- Proper investment prevents costly fines and accidents.

Why PVC Pipe Is Dangerous for Compressed Air Systems

Manufacturers explicitly warn against using some plastics for high-energy applications. Unlike water, compressed air stores explosive energy—a ruptured line can release force comparable to dynamite. Select your piping wisely to avoid deadly failures.

- Brittleness: Cold snaps make pipe walls brittle and prone to cracking.

- Adhesive failures: Temperature changes and oils cause adhesive joints to fail.

- Misleading ratings: Pressure capacity drops 50% at 110°F—most workshops exceed this.

After a PVC burst hurt staff, OSHA levied a $110,000 fine. Compression heating lowers allowable pressure even more—often ignored.

“Above-ground use of certain plastics for compressed air violates OSHA standards due to explosion risks.”

In contrast, metal pipes deform before bursting. Fragments from PVC blasts can hurl past 50 feet, embedding dangerously.

Workshops face daily temperature fluctuations that accelerate material degradation. A decade’s UV and chemical attack weakens plastic, so small leaks too often balloon into disasters.

Recommended Piping Materials for Compressed Air

Modern aluminum systems beat old-school piping on both safety and performance. They leak 90% less than black iron, making them ideal for today’s shops. Lightweight, rust-proof aluminum stands up to years of service.

Threadless modular aluminum assemblies speed assembly. Prebuilt snap-together aluminum runs come from Installation Parts Supply. One auto factory trimmed labor hours by 40% via aluminum retrofits.

- Copper: Best for cleanrooms due to natural antimicrobial properties. Requires soldering expertise.

- Stainless Steel: Resists rust in humid areas like coastal workshops.

- ABS/HDPE: For solvent-rich environments, ABS/HDPE stays intact.

“Our aluminum retrofit reduced energy waste by 15%—paying for itself in 18 months.”

Proper torque is critical. Over-tightened fittings crack, while loose ones leak. Follow manufacturer specs—typically 25–30 ft-lbs for aluminum joints.

Use NSF-certified materials when air quality is critical. Always match materials to your environment’s demands.

Material Selection Guide for Compressed Air

Consider cost, compliance, and efficiency in your pipe decision. One plant slashed $12k per year by adopting aluminum lines. Here’s how to make the right choice.

| Material | Cost (per ft) | Maintenance | ROI Time |

|---|---|---|---|

| Aluminum | $8.50 | Low | 18 months |

| Black Pipe | $5.00 | High | N/A |

| Copper | $10.20 | Medium | 24 months |

Don’t ignore thermal limits. Plastics fail under 32°F; aluminum works from -40°F to 200°F. Use stainless steel where solvents are present.

Pro Tip: Compute ROI based on compressed-air leakage. A 10% leak in a 50 HP system wastes $3,500 yearly.

- Don’t undersize—pick pipe rated at or above your compressor’s PSI.

- Keep records of inspections and tests to satisfy OSHA.

- Contact Installation Parts Supply for a no-cost audit.

“Our aluminum retrofit cut energy waste by 15%—paying for itself in 18 months.”

Hire pros for big installs to guarantee airtight connections. Check warranties—some pipes include decade-long coverage.

In Summary

Choosing the right materials for your compressed air setup isn’t just about cost—it’s about safety. Studies show 92% of failures happen in older systems, often with dangerous results. Pick aluminum for near-perfect reliability.

Key takeaways:

- Never use pipes that can fragment violently.

- Metallic lines beat plastics on both safety and durability.

- Failing to comply can cost you big in fines and claims.

Ready to upgrade? Get instant quotes and special offers from Installation Parts Supply. Download our free maintenance template or call for emergency replacements.

Invest in secure lines now to protect your crew.